- SHWY HAS FIRSTLY LAUNCHED CFU(compact fiber unit) line in CH

- he 23rd China International Optoelectronic Expo (CIOE) was g

- After the pademic outbreak in January, most factories had be

- The 5th CRU World Optical Fiber and cable conference was hel

- November 6th-8th, 2019 Wire & Cable India was held at Ne

- September 18-20, 2019 Wire Southeast was held at the Bangkok

- June 20-21,2019 Weiye was invited to attend the 8th Indian C

- The 2019 Indian 5G conference was held from 26 to 27 June. W

- Russia international pipe, wire and cable exhibition is one

- The exhibition will be held from April 2-4,2019. Founded in

- CRU’s World Optical Fibre & Cable Conference2018wa

- President of VNIIKP(Russia cable association) and SECRI(Chin

- The exhibition will be held from April 23-26,2019 at the Rub

- March 23-25,2019, the annual "Russia (Moscow) internati

- On January 29-31, 2019, we attended the Convergence India wi

- The 19thChina international optoelectronic exposition was he

- SVIAZ ICT is the most professional and largest Communication

- International Wire and Cable Trade Fair was held in Düs

- Mar 20th to 22th 2018,annual Russia CABEX was held as schedu

- On October 5th-7th2017 WIRE & CABLE INDIA was held in Pr

- Tube & Wire Southeast ASIA 2017 is a 3 day event being h

- We have participated 2017 Moscow cable show together with ou

- The 29th Svaiz ICT 2017 is jointly hosted by Russian State D

- 9th -11st, May 2017, the international event of the cable in

- Mr. Xie our founder, being the mentor of the whole OFC Equip

- We have participated in Iran cable fair in 2016 November. Th

- SHANGHAI WEIYE, Conductix (France), UNIGEL(UK), PE - Fiberop

- wire China 2016: Asia's largest event of the wire indust

- We have participated in the Russia Telecom exhibition Sviaz

- We participated in Wire Dusseldorf Germany 2016 April. The s

- Cables Saudita 2015, la feria internacional de la industria

- Our company has participated in Wire India 2014 Expo. After

- Alambre de Shanghai ha sido el espectáculo más

- Participamos en Rusia Telecom Exposición "Sviaz&

- Dusseldorf espectáculo cable es el más grande

- Vamos a participar en la exposición Sviaz Expokomm en

- Participaremos en Cabex 2014 en Moscú del 11 al 14 ma

- Participaremos en alambre, Alemania, durante 7 a 11, abril d

- La expo de Convergencia 22 se celebrará en Nueva Delh

- Nuestra empresa participó con éxito en el Bras

- Shanghai Weiyeparticipó con éxito en el alambr

Fibra óptica Dibujo de la torre

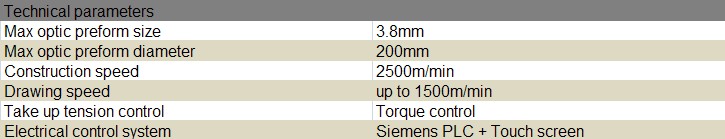

Optic Fiber Drawing Tower

Esta torre se aplica a elaborar a partir de preformas de fibras ópticas. Nuestra fábrica ha desarrollar y suministrado más de 20 torres de dibujo en China.

1 Technical specifications................................................................... 1

1.1 Fiber specification................................................................... 1

1.2 Preformspecification............................................................... 2

2 Equipment composition.................................................................. 2

2.1 Drawing tower frame............................................................... 2

2.2 Preform feeding system........................................................... 3

2.3 Fiber draw Graphite induction furnace................................... 4

2.4 Temperature keeping furnace.................................................. 7

2.6 Fiber coating diameter gauge and defect detection................. 8

2.7 Fiber cooling system.............................................................. 11

2.7.1 Cooling pipe................................................................ 11

2.8 Coating system...................................................................... 12

2.9 UV Curing system................................................................. 14

2.10 Capstans............................................................................... 14

2.11 PMD fiber spinning device.................................................. 17

2.12 DDW twin spooler............................................................... 18

2.13 Clean air system.................................................................. 19

2.14 Heating exchange and cooling............................................ 20

2.15 Mass flow controller, gas control........................................ 20

2.15.1 Vacuum Purge System............................................... 20

2.15.2 Gas and Water control cabinet for Induction Furnace......... 20

2.15.3 Mass Flow Controllers for Gas control..................... 21

2.15.6 Dynamic Iris/Sealing system and control.................. 21

2.16 100 grade air purification unit............................................. 22

2.17 Helium recovery system...................................................... 22

2.18 Auxiliary.............................................................................. 24

2.19 Control system..................................................................... 24

2.20 Centralized feeding system................................................. 25

2.21 Equipment information........................................................ 25

2.23 Utilities and environmental................................................. 25

2.23.1 UTILITIES................................................................ 25

2.23.2 ENVIRONMENTAL REQUIREMENTS................. 25

Fiber drawing machine, optical fiber proof-testing machine, optical fiber coloring machine, optical fiber ribbon machine, secondary coating line, SZ stranding line, Sheathing line, FTTH cable production line, simplex, duplex, fiber pay-off, kevlar server, extruder, Stainless teel tube production line, take-up, cable rewinding line.

Shanghai Weiye OFC Equipment Co., Ltd. Albert

Address: Guangming town, Fengxian District, Shanghai

E-mail: info@weiye-ofc.com

Phone 021 -33616519 Fax :021-33616331