News

- We supplied specialty fiber draw tower to world leading univ

- SHWY has firstly launchCFU(compact fiber unit) line in C

- he 23rd China International Optoelectronic Expo (CIOE) was g

- The 5th CRU World Optical Fiber and cable conference was hel

- November 6th-8th, 2019 Wire & Cable India was held at Ne

- September 18-20, 2019 Wire Southeast was held at the Bangkok

- June 20-21,2019 Weiye was invited to attend the 8th Indian C

- The 2019 Indian 5G conference was held from 26 to 27 June. W

- Russia international pipe, wire and cable exhibition is one

- The exhibition will be held from April 2-4,2019. Founded in

- CRU’s World Optical Fibre & Cable Conference2018wa

- President of VNIIKP(Russia cable association) and SECRI(Chin

- The exhibition will be held from April 23-26,2019 at the Rub

- March 23-25,2019, the annual "Russia (Moscow) internati

- On January 29-31, 2019, we attended the Convergence India wi

- The 19thChina international optoelectronic exposition was he

- SVIAZ ICT is the most professional and largest Communication

- International Wire and Cable Trade Fair was held in Düs

- Mar 20th to 22th 2018,annual Russia CABEX was held as schedu

- On October 5th-7th2017 WIRE & CABLE INDIA was held in Pr

- Tube & Wire Southeast ASIA 2017 is a 3 day event being h

- We have participated 2017 Moscow cable show together with ou

- The 29th Svaiz ICT 2017 is jointly hosted by Russian State D

- 9th -11st, May 2017, the international event of the cable in

- We have participated in Iran cable fair in 2016 November. Th

- SHANGHAI WEIYE, Conductix (France), UNIGEL(UK), PE - Fiberop

- wire China 2016: Asia's largest event of the wire indust

- We have participated in the Russia Telecom exhibition Sviaz

- We participated in Wire Dusseldorf Germany 2016 April. The s

- Wire & Cable Arabia 2015, the international trade fair f

- Our company has participated in Wire India 2014 Expo. After

- We participate in Russia Telecom Exhibition "Sviaz"

- Dusseldorf wire show is the biggest and most popular cable&a

- We will participate in Sviaz Expokomm exhibition in Moscow f

- We will participate in Cabex 2014 at Moscow from 11th to 14t

- We will participate in Wire,Germany during 7-11,April 2014.

- The 22nd Convergence expo will be held in New Delhi from 21s

- Our company successfully participated in theBrazil Telecom

- We successfully participated in the Wire Dusseldolf exhibiti

- Wesuccessfully participated in the Moscow Telecom exhibition

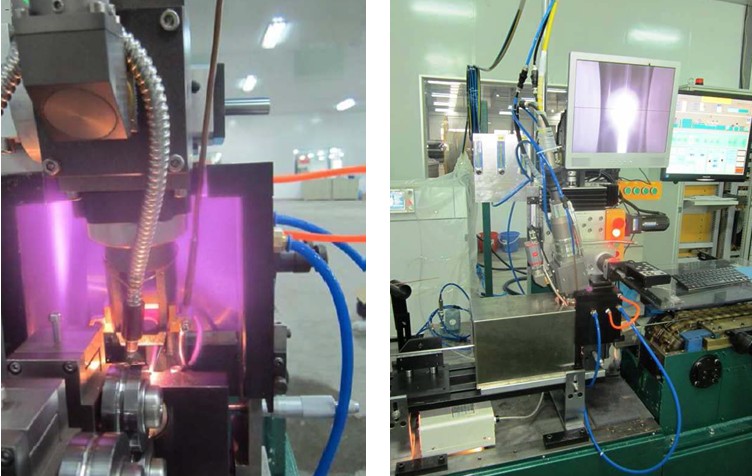

Fibers in steel tube production line (Better than Uniwema Nexans)

Fibers in metal tube production line FIMT

Our FIMT equipment is faster than European copy more than 30%. The welding speed can work in range 18-25m/min. (While European machine's welding speed is only 15m/min). Our machine is also more convenient for operation and changing forming tools.

The FIMT productin line consists of mainly the followings

Strip pay-off, fiber pay-off, Trumpf Trudisk state Laser, strip trimming and clean device, 3D welding head adjustment device & welding monitor, forming tools, jelly filling unit, clamp caterpillars units, diameter reduction unit, Disc capstan & excess length control, eddy current detector, take-up stand, electrical control system, strip splicing unit

Keywords

Shanghai Weiye OFC, Fiber drawing machine, optical fiber proof-testing machine, optical fiber coloring machine, optical fiber ribbon machine, secondary coating line, SZ stranding line, Sheathing line, FTTH cable production line, simplex, duplex, fiber pay-off, kevlar server, extruder, Stainless teel tube production line, take-up, cable rewinding line.

Shanghai Weiye OFC, Fiber drawing machine, optical fiber proof-testing machine, optical fiber coloring machine, optical fiber ribbon machine, secondary coating line, SZ stranding line, Sheathing line, FTTH cable production line, simplex, duplex, fiber pay-off, kevlar server, extruder, Stainless teel tube production line, take-up, cable rewinding line.

Contact

Shanghai Weiye Optic Fiber Communication Equipment Co., Ltd.// Head Quarter: 1036 Xizha road, Fengxian District, Shanghai // Suburb factory: Yangshi industrial park, Luoshe, Huishan district, Wuxi

E-mail: info@weiye-ofc.com // Phone 021-57525687

Shanghai Weiye Optic Fiber Communication Equipment Co., Ltd.// Head Quarter: 1036 Xizha road, Fengxian District, Shanghai // Suburb factory: Yangshi industrial park, Luoshe, Huishan district, Wuxi

E-mail: info@weiye-ofc.com // Phone 021-57525687